SPOT COLOURS

For professional printing, such as in offset printing, a spot colour is generated by an ink that can either be pure of mixed. This would be printed in a single run, as in each individual plate per colour.

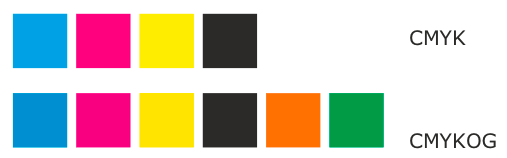

Offset printing processes uses and composes four spot colours, which are Cyan, Magenta, Yellow and Key (Black), this is CMYK. There are however other, more advanced processes which involve using six spot colours. This is a hexachromatic process, designed by Pantone it adds Orange

Spot colours however are not just process colours, it is also a term in order to mean any colour that can be generated and be a pure mix. These are generated by a non-standard offset ink, that can be metallic, fluorescent, spot varnish or custom hand-mixed inks.

In any offset printing process, each spot colour needs to have its own lithographic film, and each colour to be printed will be printed using the same individual plate assigned. There are different aspects within printing spot colours that will need to be changed and vary according to its intended purpose, these include, dot gain and screen angle.

DOT GAIN (also known as Tonal Value Increase) is a phenomenon in offset lithography and some other forms of printing which causes printed material to look darker than intended. It is caused by halftone dots growing in area between the original printing film and the final printed result.

SCREEN ANGLE in offset printing, the screen angle is where the halftones of a separated colour are outputted to a lithographic film, hence, printed on final product media. Failing to use the correct set of angles to output every colour may lead to some kind of optical noise called moiré patterns. These patterns look like some bands or waves that mostly lead to unpleasant look of the final print.

Spot colours are great for perfect matching of colour, assigned from Pantone, to exactly the colour you want. Pantone has worked hard to be able to standardize and categorise all colours in order to match the spot colour print to the monitors colour. Down to obvious reasons printed colours and monitor colours are going to be different, CMYK vs RGB. To achieve a balance between what you want and what is printed, it is a good idea to have a proper monitor calibration to prove information is correct in the process of sending to print.

Generally the cost and potential for problems for a print job increase as you add more spot colours, due to the increased cost and complexity of added process inks and films, and requiring more runs per finished print. However, spot colours can be a very powerful weapon in security printing, like money, passports, bonds, and other similar prints that should be hard to forge. Money printing for example, uses secret formulae of spot colours, some of which can be seen by the naked eye, and some cannot be seen unless by using special lights, or by applying certain chemicals.

SPOT VARNISH

Spot varnishing is a special effect that puts varnish only on specific areas of a printed piece. Use spot varnish to make a photograph pop off the page, highlight drop caps, or to create texture and subtle images on the page. In page layout programs, you specify spot varnish as a new spot colour.

No comments:

Post a Comment